Printable Welder Performance Qualification Record Template

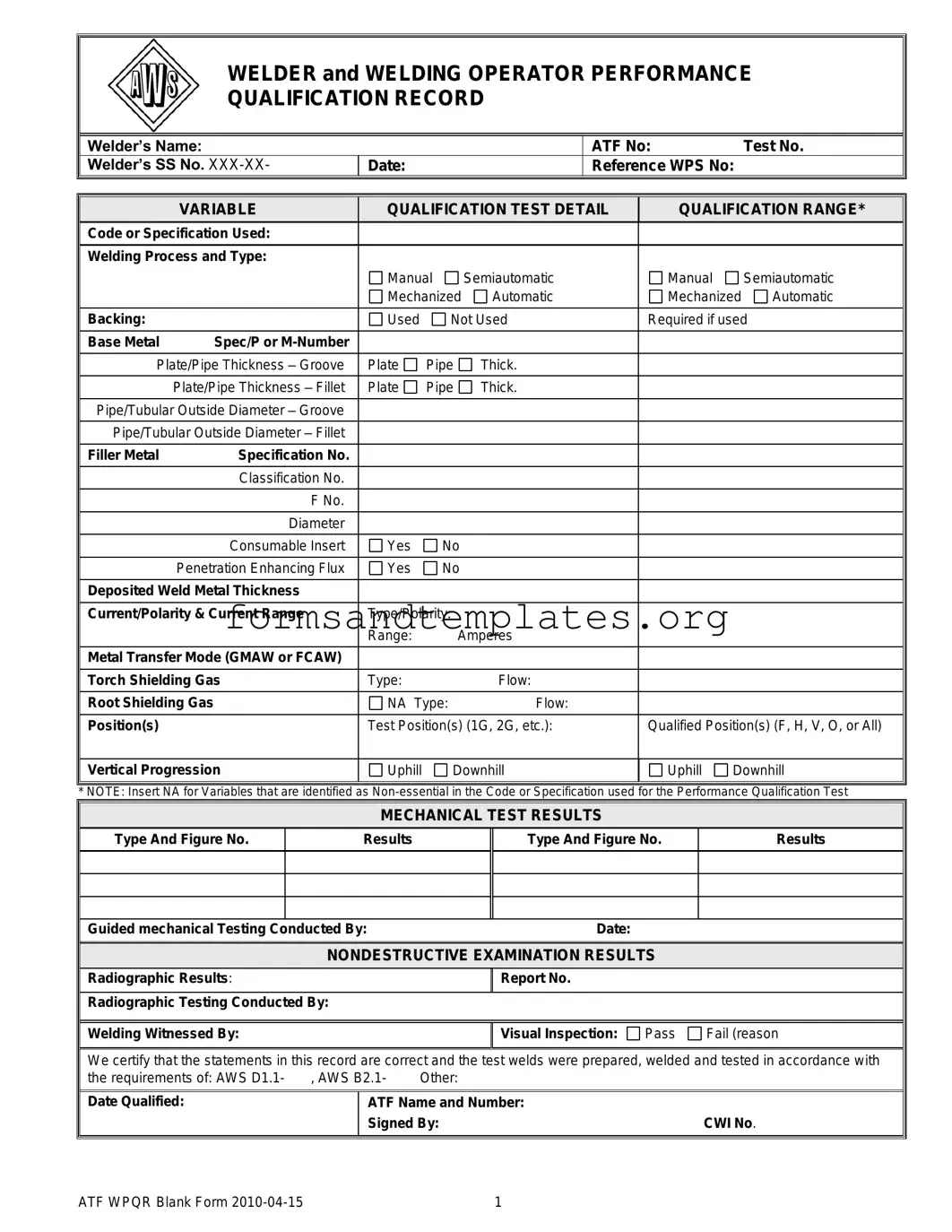

The Welder Performance Qualification Record (WPQR) form is an essential document in the welding industry, serving as a comprehensive record of a welder's qualifications and capabilities. It includes critical information such as the welder's name, identification numbers, and the specific test details that validate their skills. The form outlines various aspects of the welding process, including the type of welding performed—whether manual, semiautomatic, mechanized, or automatic—and the specifications of the base metal used. Additionally, it captures vital variables like plate thickness, filler metal specifications, and the positions in which the welder is qualified to work. The WPQR also records the results of mechanical tests and non-destructive examinations, ensuring that the welder meets industry standards. This document not only serves as proof of a welder's abilities but also plays a crucial role in maintaining safety and quality in welding practices. By providing a detailed account of qualifications, the WPQR helps employers assess the competency of welders for specific projects and ensures compliance with relevant codes and specifications.

Common mistakes

-

Incomplete Information: Failing to fill in all required fields, such as the welder’s name, ATF number, or test number, can lead to significant delays in processing the qualification record.

-

Incorrect Specification Reference: Using the wrong WPS number or code specification can result in disqualification of the test, as it may not align with the required standards.

-

Omitting Essential Variables: Neglecting to indicate whether backing was used or required, or leaving out details about the filler metal specification, can cause confusion during evaluation.

-

Improper Test Position Notation: Misidentifying the test position (e.g., 1G, 2G) or the qualified positions (F, H, V, O) can lead to incorrect assessments of the welder's capabilities.

-

Missing Mechanical Test Results: Failing to include results from guided mechanical testing or neglecting to provide the name of the testing entity can undermine the validity of the qualification.

-

Inaccurate Non-Destructive Examination Results: Providing incorrect radiographic results or failing to document visual inspection outcomes can lead to questions about the weld quality.

-

Signature and Date Errors: Not securing the required signatures or omitting the date qualified can render the qualification record invalid, as proper authorization is essential for compliance.

Find Common Documents

Release of Lien Texas Property - Holders of notes and liens must complete this form after receiving full payment.

Warranty on Roof - Each warranty is unique to the specific installation address and owner.

Creating a Last Will and Testament is a vital step in planning for the future, as it helps guarantee that your assets are distributed according to your wishes and your loved ones are cared for. To ensure that this important document meets all legal requirements in California, you might want to explore resources such as California Templates, which provide easy-to-use forms and guidance for securing your legacy.

Affidavit of Death of Joint Tenant - The affidavit can also be useful in situations involving multiple trustees.

Key takeaways

Filling out the Welder Performance Qualification Record form is crucial for documenting a welder's skills and qualifications. Here are key takeaways to keep in mind:

- Accurate Information: Ensure that all personal details, such as the welder’s name and Social Security number, are filled out accurately.

- Reference WPS: Include the correct Welding Procedure Specification (WPS) number. This links the qualification to the specific welding standards.

- Variable Qualification: Clearly indicate the qualification range. This includes various factors like base metal thickness and type of welding process used.

- Mechanical Test Results: Document the results of any mechanical tests conducted. This verifies the quality of the welds.

- Non-Destructive Examination: Include results from any non-destructive tests, such as radiographic testing. This helps confirm the integrity of the welds.

- Visual Inspection: Record the outcome of the visual inspection. A clear pass or fail status is essential for compliance.

- Certification: Ensure that the record is signed by a Certified Welding Inspector (CWI). This adds credibility to the qualifications.

- Use of NA: For non-essential variables, write "NA" where applicable. This helps clarify which qualifications are relevant.

- Keep Records: Maintain a copy of the completed form. This serves as a reference for future qualifications and job applications.

Understanding these key points will help in accurately filling out and utilizing the Welder Performance Qualification Record form.

Welder Performance Qualification Record Example

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

|

Welder’s Name: |

|

|

|

|

ATF No: |

|

Test No. |

||||||

|

Welder’s SS No. |

|

Date: |

|

|

Reference WPS No: |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

VARIABLE |

|

|

QUALIFICATION TEST DETAIL |

|

|

QUALIFICATION RANGE* |

|

|||||

|

Code or Specification Used: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Welding Process and Type: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Manual |

Semiautomatic |

|

|

Manual |

|

Semiautomatic |

|||

|

|

|

|

|

Mechanized |

Automatic |

|

|

Mechanized |

Automatic |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

Backing: |

|

|

|

Used |

Not Used |

|

|

Required if used |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Metal |

Spec/P or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Plate/Pipe Thickness – Groove |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Plate/Pipe Thickness – Fillet |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Groove |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Fillet |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filler Metal |

Specification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Classification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Consumable Insert |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Penetration Enhancing Flux |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Deposited Weld Metal Thickness |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Current/Polarity & Current Range |

|

Type/Polarity: |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Range: |

Amperes |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Metal Transfer Mode (GMAW or FCAW) |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Torch Shielding Gas |

|

Type: |

|

Flow: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

Root Shielding Gas |

|

NA Type: |

Flow: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

Position(s) |

|

|

|

Test Position(s) (1G, 2G, etc.): |

|

|

Qualified Position(s) (F, H, V, O, or All) |

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Vertical Progression |

|

Uphill |

Downhill |

|

|

Uphill |

Downhill |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* NOTE: Insert NA for Variables that are identified as

|

|

|

|

MECHANICAL TEST RESULTS |

|

|

||

|

Type And Figure No. |

|

|

Results |

|

Type And Figure No. |

Results |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guided mechanical Testing Conducted By: |

|

Date: |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

NONDESTRUCTIVE EXAMINATION RESULTS |

|

|

|||

|

Radiographic Results: |

|

|

|

Report No. |

|

|

|

|

|

|

|

|

|

|

||

|

Radiographic Testing Conducted By: |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welding Witnessed By: |

|

|

|

Visual Inspection: Pass |

Fail (reason |

) |

|

|

|

|

|

|||||

|

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with |

|||||||

|

the requirements of: AWS D1.1- |

, AWS B2.1- |

Other: |

|

|

|||

|

|

|

|

|

|

|||

|

Date Qualified: |

|

ATF Name and Number: |

|

|

|||

|

|

|

|

Signed By: |

CWI No. |

|

||

|

|

|

|

|

|

|

||

ATF WPQR Blank Form |

|

|

1 |

|

|

|||

Understanding Welder Performance Qualification Record

What is the purpose of the Welder Performance Qualification Record form?

The Welder Performance Qualification Record (WPQR) form serves to document a welder's qualifications. It verifies that the welder has passed specific tests according to industry standards. This record is essential for ensuring that welders are skilled and capable of performing their tasks safely and effectively.

What information is required on the WPQR form?

The WPQR form requires several key pieces of information, including:

- Welder’s name and identification numbers

- Test number and date

- Welding Procedure Specification (WPS) reference number

- Details about the welding process, including type and position

- Mechanical test results and non-destructive examination results

- Signatures from qualified personnel

This information helps verify the welder's capabilities and compliance with relevant standards.

How is the performance qualification tested?

The performance qualification is tested through practical welding tests that assess the welder's skills. These tests can include various welding processes, positions, and materials. The results are then documented on the WPQR form. Depending on the requirements, tests may also involve mechanical testing and non-destructive examination to ensure the quality of the welds.

What does "qualified position" mean?

The term "qualified position" refers to the specific welding positions in which a welder is certified to work. Positions are categorized by numbers and letters, such as 1G, 2G, F, H, V, and O. A welder must demonstrate proficiency in these positions during testing to be qualified for that specific type of work.

What happens if a welder fails the qualification test?

If a welder fails the qualification test, they cannot use the WPQR to certify their skills. The welder may need to undergo additional training or practice before retaking the test. It is important for welders to achieve a passing grade to ensure they meet industry standards and maintain safety in their work.

How long is the qualification valid?

The validity of the qualification can vary based on the specific standards and regulations in place. Generally, a performance qualification remains valid as long as the welder continues to perform welding tasks regularly. However, if a welder has not welded for an extended period, they may be required to retake the qualification test to ensure their skills are up to date.

How to Use Welder Performance Qualification Record

Completing the Welder Performance Qualification Record form is essential for documenting a welder's qualifications and ensuring compliance with industry standards. Follow these steps carefully to ensure all necessary information is accurately recorded.

- Begin by entering the Welder’s Name at the top of the form.

- Fill in the ATF No and Test No fields.

- Provide the Welder’s SS No in the designated area.

- Record the Date of the qualification test.

- Input the Reference WPS No as required.

- Specify the Code or Specification Used for the qualification.

- Indicate the Welding Process and Type by checking the appropriate boxes (Manual, Semiautomatic, Mechanized, Automatic).

- Note if Backing was used or not, and if it was required.

- Fill in the Base Metal Spec/P or M-Number along with the Plate/Pipe Thickness for both Groove and Fillet welds.

- Enter the Pipe/Tubular Outside Diameter for both Groove and Fillet welds.

- Provide details on the Filler Metal Specification No. and Classification No..

- Specify the F No. and Diameter of the filler metal.

- Indicate if a Consumable Insert was used (Yes/No).

- Note if Penetration Enhancing Flux was utilized (Yes/No).

- Record the Deposited Weld Metal Thickness.

- Fill in the Current/Polarity & Current Range, including Type/Polarity and Range in Amperes.

- Specify the Metal Transfer Mode (GMAW or FCAW).

- Provide details about the Torch Shielding Gas Type and its Flow.

- Indicate the Root Shielding Gas type and its Flow, if applicable.

- List the Test Position(s) (1G, 2G, etc.) and the Qualified Position(s) (F, H, V, O, or All).

- Specify the Vertical Progression as either Uphill or Downhill.

- For the MECHANICAL TEST RESULTS, enter the Type and Figure No. along with the Results.

- Document who conducted the Guided Mechanical Testing and the Date it was conducted.

- In the NONDESTRUCTIVE EXAMINATION RESULTS section, provide the Radiographic Results and Report No.

- Indicate who conducted the Radiographic Testing and who witnessed the welding.

- Complete the Visual Inspection result (Pass/Fail) and provide the reason if it failed.

- Finally, certify the accuracy of the statements by filling in the Date Qualified, ATF Name and Number, and have it Signed By the appropriate individual.

- Include the CWI No. at the end of the form.